Курсовая работа: Planning of mobile complete set for a rural wind generator

Kw is the winding factor and depends on the winding arrangements and has a value less than unity. Distribution factor Kd and a short pitch factor Kp reduces the winding voltage magnitudes but also reduces certain harmonics in EMF and MMF waveforms.

![]() (Eq. 3.12)

(Eq. 3.12)

Distributed winding configuration has one slot per pole per phase and its winding factor is equal to 1.

B. Winding arrangement

Single layer winding, where each slot contains one coil side, will be used in this design as it is economical to manufacture and has simpler end connection. Emf and mmf can be modified to reduce harmonics. In a three phase system even harmonics do not appear due to the winding symmetry, the only visible harmonics are the belt harmonics.

C. Winding Pitch

Short pitch is the most commonly used type of winding pitch. It reduces the distorting harmonics and produces a truer sinusoidal wave. The length of the end connection is also reduced thereby saving copper and reducing copper loss in the coil.

The drawback of short pitch winding is that the induced emf in it is smaller than in a full-pitch coil. The reason is that the total flux linking the short-pitch coil is smaller than that of the full-pitch coil.

3.6.9 Number of turns

The number of turns per pole is estimated to be 60 turns from equation 3.11.

The design parameters discussed will be modelled in FEMM in the next chapter to induce the output voltage and flux of the generator.

Chapter 4. Modelling the design in FEMM

4.1 Introduction

The investigation that will follow focuses on the effect of substituting standard commercial magnets with recyclable speaker magnets that were collected from a dumpsite in the village, to compare the performance of the generator in either case.

In this chapter, the two pole generator geometry discussed in chapter 3 will be modelled in FEMM to analyse the output induced voltage and the flux of the generator. The lua-script in FEMM is run and the rotor is rotated 360 electrical degrees, for the lua-script refer to appendix C1.

Initially, a choice was made of three typical commercial magnet grades. Neodymium-iron-boron NdFeB was chosen from the rare-earth magnet group. Alnico6 was chosen from the Alnicos and the last type was barium ferrite from the ferrite or ceramic group. Then the machine will be modelled using different types of commercial magnets to investigate the performance of the generator.

The author then proceeded to investigate the magnetic properties of the loudspeaker magnet. This was done so that the parameters can be modelled in the finite element package.

Finally a design using the loudspeaker magnets was modelled to explore the recycled generator output.

4.2 Two pole geometry

Table 4.1 below summarizes the generator specifications that were discussed in chapter 3. These parameters will be modelled in FEMM to view the output induced rms voltage and the flux.

| Quantity | Value |

| Frequency | 39.79Hz |

| Poles | 2 |

| Connection | Y |

| Diameter of Rotor | 50mm |

| Machine Depth | 15mm |

| Air gap length | 0.5mm |

| Turns per phase | 80 |

| Stator slots | 6 |

| Steel Core | 1020 steel |

Table 4.1 Data of designed PM machine

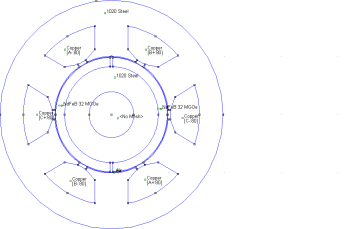

The design is modelled in FEMM and is illustrated in figure 4.1 below.

Figure 4.1 The generator modelled in FEMM

4.3 Commercial magnets

To investigate the performance of the generator, the author began by modelling the generator with standard commercial magnets with the properties given in table 3.1. The output rms emf and flux of the generator is tabulated in table 4.2 with different magnets that were used in the design.

Refer to appendix B for the graphs of the outputs. Matlab soft ware was used to draw the output rms emf and the flux, matlab code included in appendix C2.

Table 4.2 Generator output with commercial magnets

| Magnet | Type | Flux (Rms) | EMF (Rms) |

| Rare-Earth | NdFeb32 | 0.0459 | 9.4262 |

| Alnico | Alnoco6 | 0.0186 | 5.1619 |

| Ceramic | Ceramic8 | 0.0175 | 3.6075 |

4.4 Recyclable magnet found in the rural area

The magnet that was used in this section was from a loudspeaker that was found lying in one of the dumps at Ga-Rampuru village. To start with the magnet shape was not of concern. The author aimed to investigate the performance of the magnet on the speaker if used as it was found. The properties of this magnet were investigated and a design was modelled using these magnets. The magnet is shown below in figure 4.2.

4.4.1 Background on the characteristics of loudspeaker magnets

For speaker applications, the amount of permanent magnet required is directly proportional to the rated output power of the speaker. In other words high power speakers are often made using the high-grade magnetic types like the rare-earth. But since the speakers found in the dumpsite were from low power appliances their typical magnets are normally from the ceramic group type. In addition unlike Alnico magnets, ferrite or ceramic magnets are not easily demagnetised magnetized and hence find wide application in such appliances.

4.4.2 Properties of the loudspeaker magnet

According to its nameplate the speaker that used the magnet in figure 4.3 had a 0.5W rms and an impedance of 8 ohm. The magnet type on the loudspeaker is a ferrite [Refer to appendix D1]. The manufacturer of the magnet on the speaker is traced in order to find the B-H properties of the magnet on the speaker.