Курсовая работа: Development of technology of crude smoked sausage

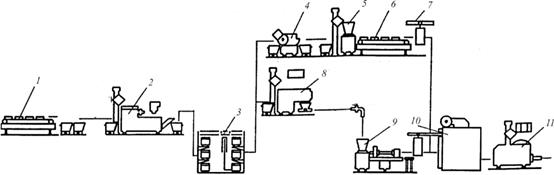

Fig. 3 Technologicalschemeof the enzymaticcrude smokedsausage.

3.2 Technological line for dry enzymatic sausage production

1,6- conveyor table; 2- brining unit; 3- cell maturation; 4- cup-shaped cutter;5- syringe machine; 7- sausage frame; 8- sausages unit; 9- heat chamber; 10-smoking device.

Fig. 4 Technological line for dry enzymatic sausage production

After defrosting the meat is sent to the trimming section: where connective tissue, blood and lymph vessels, cartilage, small stones and dirt are removed. 1. Then meat is cut into the small pieces and frozen lightly.

Salting of chopping meat is carried on brining unit 2. Minced meat falls by gravity from unit into the mixer. Salting substances are given by dosing device in quantity proportion to the mass of minced meat in vat mixer. After mixing and unloading of raw materials in trucks sent to the cell maturation 3.

Protein "PP500E" and meat pulverized using cup-shaped cutter 4 for fine grinding and preparing meat. To a syringe machine 5 beef shipped in outdoor carts that are using the lift to unload hopper syringe. In this case, the molding meat loaves made by hand in cutting the shell with one end, followed by items made up of hand-knitted twine sticks on conveyor table 6 and dumping them into sausage frame 7.

Shaping the manufacture of sausage casings of roll material is carried out on sausages unit 8.

After mating, or overlay hinges sticks hung on sticks, which are then placed on the frame 7 and sent to the heat chamber 9 for heat treatment (precipitation). Next sausage sent to a smoking device 10, and after subjected to drying 11.

During ripening and drying in the minced meat is a few important changes. These include changes in the number of different species of bacteria, physical changes, such as changes in pH and moisture content, as well as chemical changes, such as gidralisation protein into amino acids and ammonia.

3.3 Technology introductions of protein of software 500Е

Owing to wide assortment of this kind of production I have chosen modern technology with protein introduction «Purin 500Е» and with use of bacterial ferments on purpose to provide a controllable fast fermentation the Product should be ready to realization in 21 days, but it, basically, depends on diameter of a cover.

First, I will stop on a method of introduction of protein «PP 500Е» in crude smoked sausages.

The maximum advantage gives addition «software 500Е» in the form of gel of squirrels: water with a parity of squirrels: water equal 1:3,5 — 1:4. The technique consists in the following:

— «PP 550Е» crush Squirrels in cutter in the presence of 3,5-4 parts of water before full hydration (about 1-2 minutes). The weight turns out smooth shining porridge formed.

— to this gel add blood in quantity approximately 2 % on purpose to compensate color. Good way is also heart crushing together with gel. Heart provides good pigmentation, is high-quality offal, raises profitability of manufacture. In this case heart is used in number of 10-20 %.

Gel can be painted also, adding the natural painted spices, for example, a paprika.

— at last, in cutter enter 2-3 % of salt and 70-150 mg/kg of nitrite.

The above-stated technique provides reception of strong gel which can be stored in refrigerating conditions (to +2 OS) during the certain period of time, or it can be frozen.

Approximately 5-12 % of the gel received thus can be entered into mincemeat that gives the chance to save meat raw materials and to raise profitability of manufacture.

In the table 2 the compounding resulted on this slide can be example of compounding of the crude smoked fermented sausage [13].

Table 2

The recipe ofdryfermentedsausages.

| Recipe: | kg |

| Leanpork | 27 |

| Leanbeef | 27 |

| Fatback | 34 |

| Gelprotein"PP 500E" inwater | 12 |

| Total | 100 |

| Salts | 2,5 |

| Nitrite | 0,014 |

| Ascorbic acid | 0,10 |

| Sugars | 1,5 |

| Seasonings | arbitrarily |

The protein content of"PP 500E" in the finalproductis 2%.

Preparation recipe of gel is shown in the table 3.

Table 3.

Recipeof gel

| Recipegel: | kg |

| «PP 500Е» | 2 |

| Water | 7,8 |

| Pigheart | 2 |

| A mixture of95% saltand 5% nitrite | 0,2 |

| Nitrite | 0,001 |

| Total | 12,0 |

3.4 Grocery calculation dry enzymatic sausages

Schedule ofworkshopsbasedonthe chartentryof raw materials, by laborlaw ofRK, it takes into accountthe valuationof the workingdayworkers. Number ofshiftsper day-2, the shop is workingall the time,as the raw materialarriveseveryshift.